Why does red brick still useful in Building?

Although red bricks are a common choice for residential structures, it's crucial to make sure the colors match exactly.

Red bricks can be assembled into complicated shapes and designs by utilizing interlocking techniques with cement or adhesives.

Aggregate, water, and clay are combined to make red bricks. They are still incredibly common now, having existed for over 10,000 years.

Red bricks are compact and manageable, have a high compressive strength, are long-lasting, and require minimal maintenance.

Among the most traditional and widely used building materials, brick is still a top choice for construction projects. It is inexpensive, strong, manageable, and simple to use. The fundamental building material for a house is a red or clay brick.

Bricks are rectangular in shape and large enough to be handled with one hand in the traditional sense. Burned clay or a sand and lime mixture is used to make red bricks. They are widely utilized since they are affordable and widely accessible.

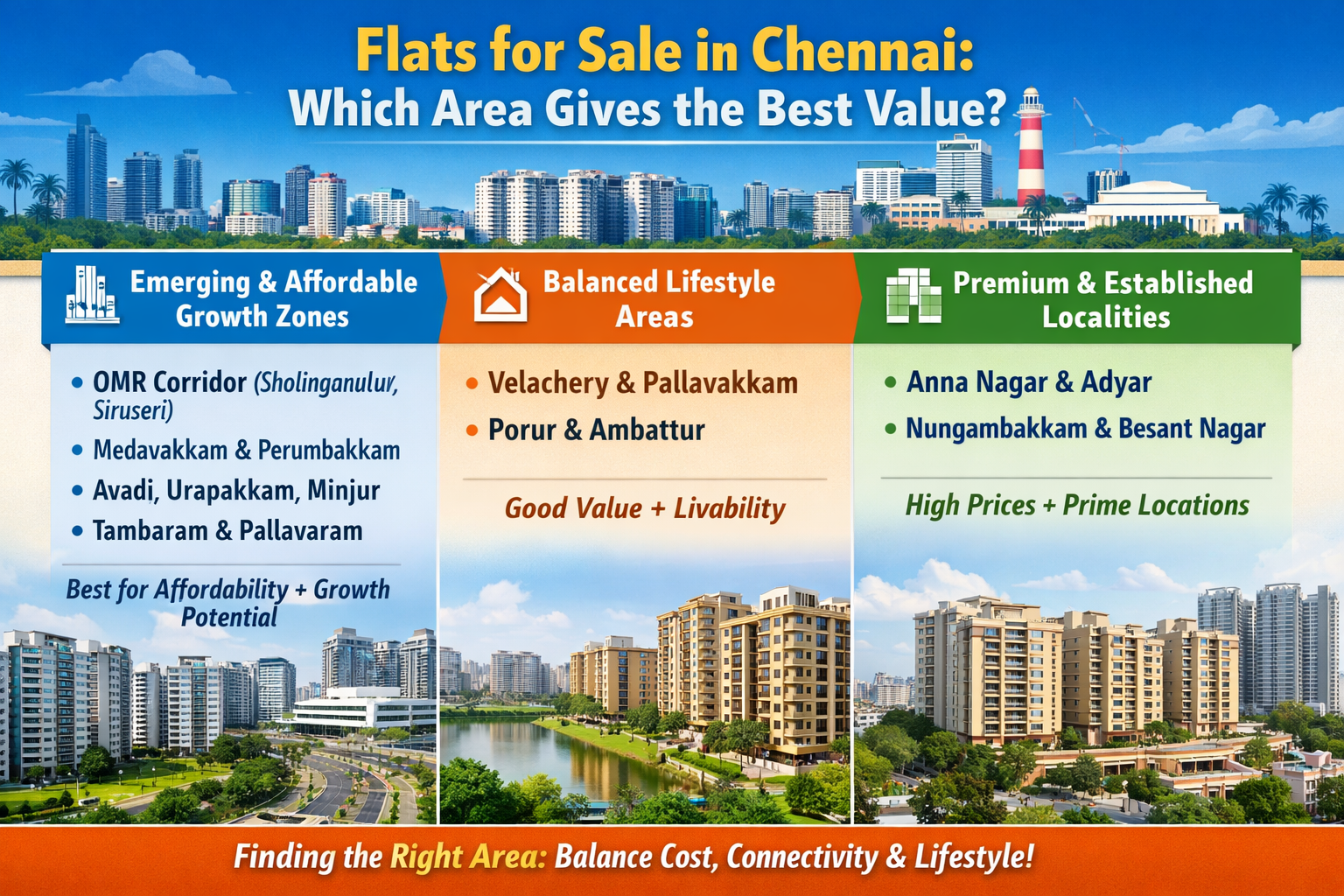

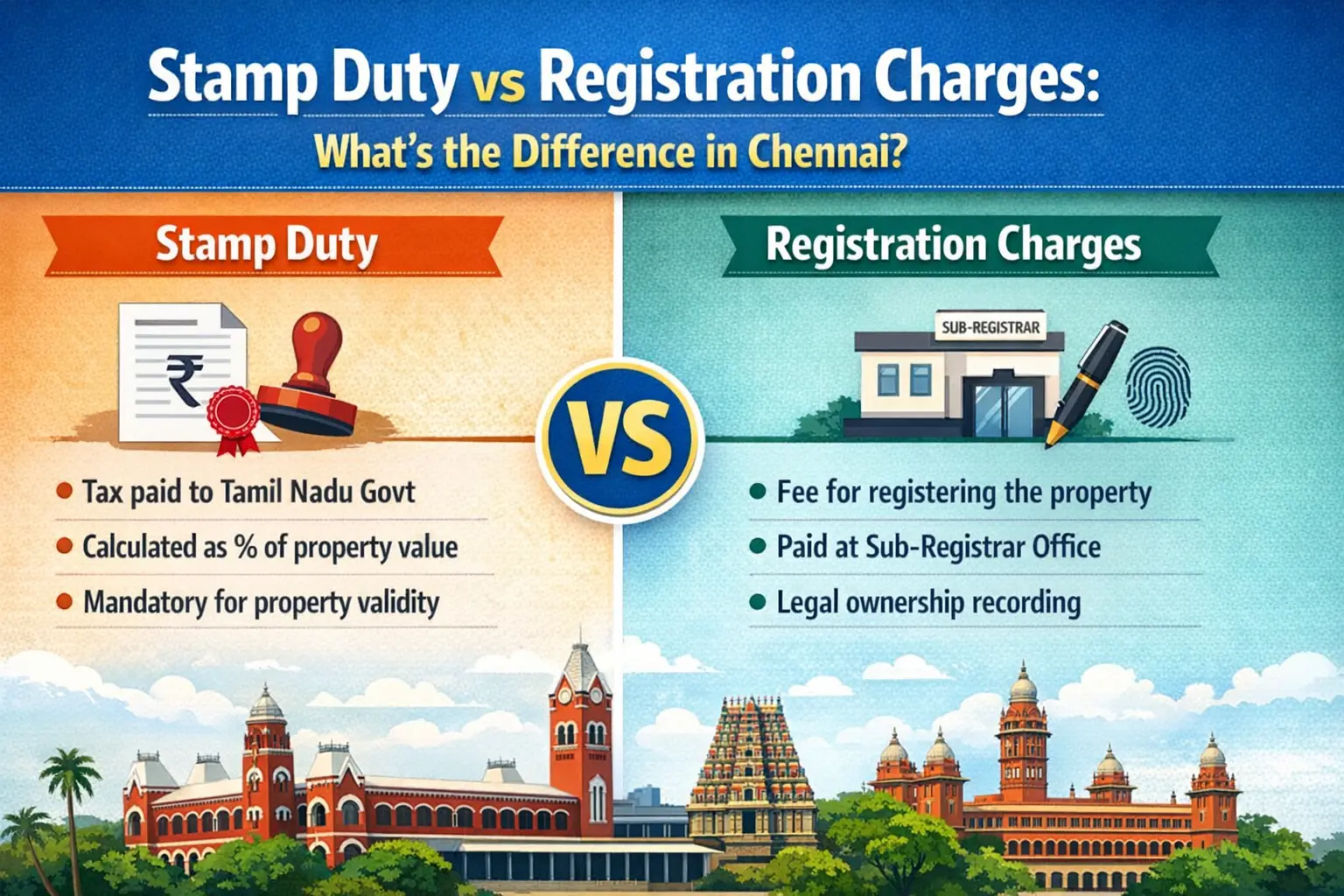

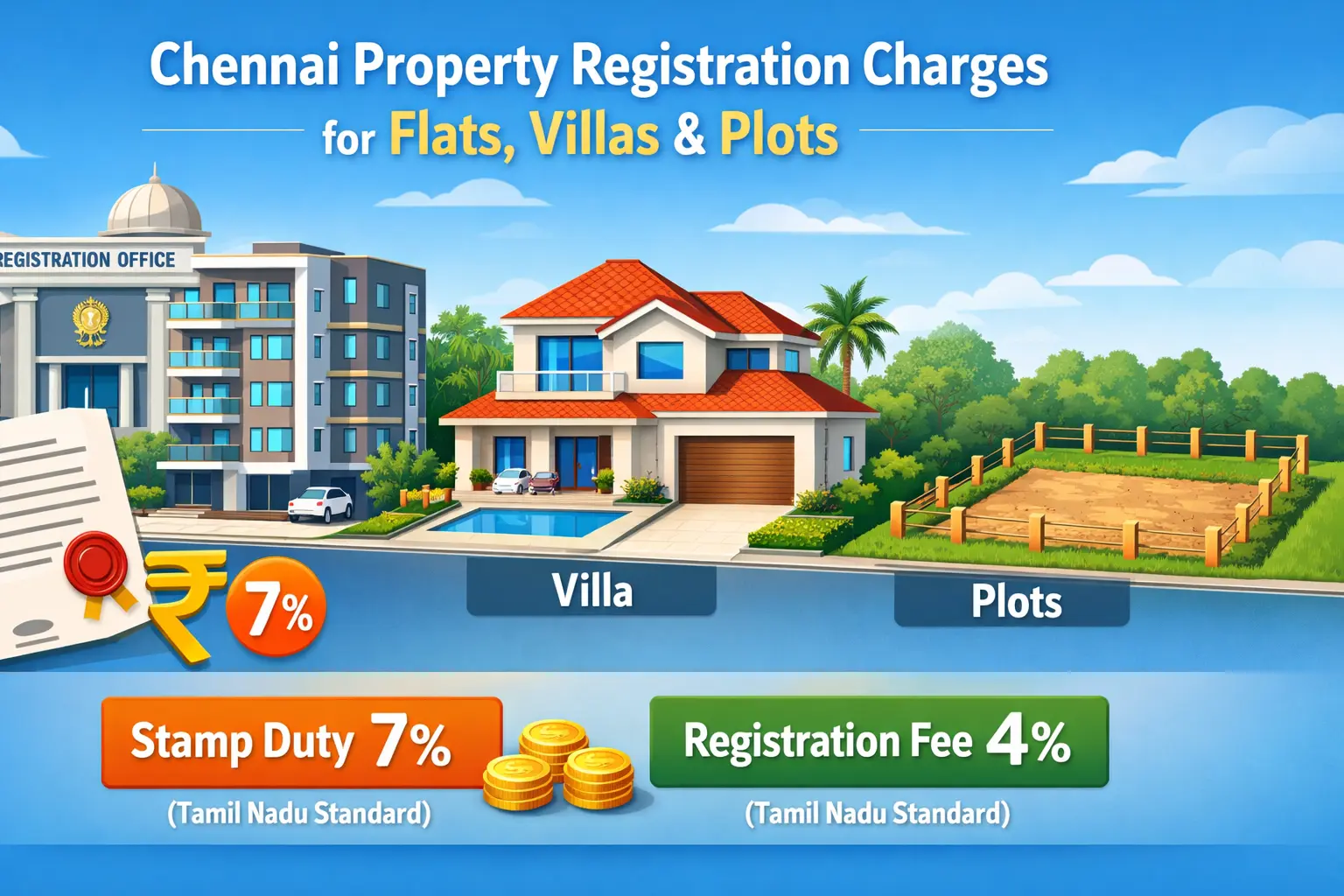

| Best Builder Floor Apartment in Chennai |

WHY RED BRICK IS USED?

Structures built using traditional red bricks are said to be more durable than those made of hollow blocks.

For the structural construction of buildings, arches, pavement, bridges, and foundations, red bricks can be utilized. In addition, these can be employed for many other architectural uses, such as beautification and exterior projects.

Red brick homes require little upkeep and can endure for at least 100 years. Red brick homes have an estimated 500 years of lifespan with proper servicing, such as repointing the mortar

Red bricks are environmentally benign and fully decompose since they generate very little waste and pollutants. A red brick's compressive strength is sufficient for any typical structure

Red Bricks can be divided into two groups:

1. Depending on the production process; and

2. Depending on the shape

Red bricks are grouped as follows according to the production process:

1. Sun-dried or unburned bricks

Bricks that have not burned are manufactured from clay that has been molded and then dried using heat from the sun. Because of this, these red brick varieties aren't extremely durable and can't be utilized in permanent construction. Because unburned bricks are less strong, they are utilized in temporary constructions.

2. Burnt clay bricks

Although clay is burned in a kiln inside the factory, the burned clay is also used to make burned clay bricks. The most popular varieties of red brick for usage in construction projects are these ones. Burnt bricks have a high caliber. Nevertheless, burnt clay bricks are divided into four categories of red brick due to various flaws they may have:

♦First Class Bricks

Compared to other classes, first class bricks are of higher quality. Fine plastic soil that is devoid of salt deposits is used to make fine bricks. Table-moulding is used to mold premium bricks, which are then burned in huge kilns. Their size is uniform. Their colors are all the same. When two bricks are struck together, they produce a strong, ringing sound, indicating that they are well burned. Their surfaces are even and their edges are straight. They don't have any chips, cracks, imperfections, or lime nodules. They are durable and absorb less water.

Uses: Premium bricks are utilized for long-term constructions such as exterior walls, flooring, arches, and reinforced brickwork. They cost more than other brick classes

♦Second Class Brick

Kilns are used to burn second-class brick, which is ground-molded. Second-class bricks are slightly different in shape and color from first-class bricks, but they still fit the required dimensions. In addition, they are completely charred, and striking two bricks together produces a ringing sound. In contrast to first-class brick, it could have small fractures and uneven, sharp edges.

Uses: For exterior plastering projects, such as partition walls and compound walls. It can also be applied to interior projects, but not flooring. Their tensile strength and water absorption are higher

♦Third Class Bricks

Third-class bricks have a reddish-yellow color because they haven't burned completely. They have uneven, twisted edges, rough surfaces, and are not very hard. They absorb a lot of water and are weaker.

Uses: These bricks are utilized for small-scale, transitory constructions as well as areas with light rainfall, such as paving and tiny brick foundations

♦Bricks of the Fourth Class

As a result, fourth class bricks are of extremely low quality. After being overburned, they are crushed and used as aggregates. Because of this, they are brittle and inappropriate for the building's major component.

Fourth Class Bricksare divided into two categories:

•Zhamas: Zhamas are extremely irregularly shaped, overburned bricks that fuse together when they are close to the kiln fire. It is not employed in routine engineering tasks.

•Pilas: Pilas are yellow-colored bricks that have been partially or completely burned. When dropped on hard surfaces, their strength is quite low, and they break easily.

Uses: These bricks are utilized as concrete aggregate for roads, floors, and foundations.

Qualities of a Good Brick

1. Brick Earth

Considering these materials lead to lower-quality bricks, brick soil should be free of organic matter, stones, pebbles (kankars), and other hazardous chemicals.

2. Size of a Brick

Standards state that a good brick should be the same size, with smooth, rectangular surfaces, parallel sides, and straight, sharp edges. Bricks should have tolerances of no more than 3 mm for length and 1.5 mm for breadth and height. Clay bricks are typically 190 x 90 x 90 mm in size, according "IS 1077: 1992" (Common Burnt Clay Building Bricks - Specification). Even in large nations like India, the size of bricks can differ from one location to another and from one country to another

3. Shape

A brick should have a homogeneous shape. A quality brick should have edges that are straight, sharp, and at the proper angle. Bricks intended for certain uses, however, can be produced in a variety of varied forms or cut. Usually, these are variations on rectangular forms

4. Color

There is a vast array of colors, including some intermediate tints including red, white, grey, brown, purple, blue, and black. W. B. McKay, the author of Building Construction, claims that the chemical makeup of the clay, its temperature while burning, the kiln's air conditions, and staining all have an impact on color. High-quality bricks should have a consistent color throughout their body and should be well burned. Bricks that are overburned or underburned lose their strength and surface color consistency. Extremely intense red hues denote burned bricks above, whereas yellow hues denote burned bricks beneath

5. The Frog in the Brick

A high-quality brick should have an appropriate frog, or the depression created on the brick's face during molding, to allow the mortar to fill the frog appropriately. The frog's dimensions should be 40 mm wide, 10 mm deep, and 100 mm long

6.Texture and Compactness

Brick textures differ significantly from one another. The texture of high-quality bricks should be consistent and pre-compacted. Brick surfaces shouldn't be very smooth to allow mortar to slide off them. There shouldn't be any lumps of lime, grit, holes, or fissures on a broken surface.

7. Compressive Strength

Brick's compressive strength is determined by the type of clay and level of burning. According to the 1983 "National Building Code of India," brick must have a minimum compressive strength of 3.5 N/mm2, or 35 kg/cm2. Additionally, we have a piece on how to determine the brick's compressive strength.

8. Firmness

Bricks should to be a decent enough hardness. A brick should not have any impressions made on it.

9. Water Absorption

A good brick should absorb no more water than 20% of its dry weight after a 24 hour immersion. After being submerged in water for a whole day, bricks are not supposed to exhibit any white salt deposits while drying in the shade. After being soaked in water for 24 hours, bricks should not absorb more water than 20% of their weight, especially first-class bricks, and 22% of their weight for second-class bricks. Testing in a lab is necessary to determine whether bricks can absorb water

`

10. Soundness

The brick should make a metallic ringing sound when hit with a hammer or another brick

Red bricks provide a number of benefits.

Benefits:

1. Durability: Red bricks are long-lasting and strong.

2. Thermal mass: Their high thermal mass contributes to the ability to control interior temperature.

3. Fire resistance: One important safety attribute of red bricks is their resistance to fire.

4. Aesthetics: A lot of individuals find red bricks' organic, earthy appearance to be appealing

Red Bricks Sustainability And Eco-Friendliness

Natural resources: Red bricks don't require the energy-intensive processes that some other building materials do because they are created from natural clay and sand. Because of this, they are a sustainable option in terms of raw materials.

Recyclability: Red bricks are recyclable and can be crushed and used as a base material for future construction projects, which minimizes the waste's negative environmental effects

Energy efficiency: Red bricks, as previously indicated, naturally insulate a building, lowering the amount of energy required to heat or cool it. As a result, the structure has a reduced carbon footprint and emits less carbon.

Longevity: Red bricks are long-lasting, thus buildings made of them may withstand the test of time and require fewer demolitions and reconstructions over time

— - —