Are you Know about the Use of Fly Ash Bricks in Construction?

What are fly Ash bricks?

Fly ash bricks are made through the combination of fly ash with cement, sand, and water. Power stations can burn coal and produce fine, powdery fly ash. It is collected by electrostatic precipitators and other pollution control equipment before being released into the atmosphere. Fly ash is a waste material that can be repurposed to make bricks. Using fly ash in brickmaking can lessen the environmental impact of coal-fired power stations while conserving natural resources such as clay, which is usually used in brickmaking.

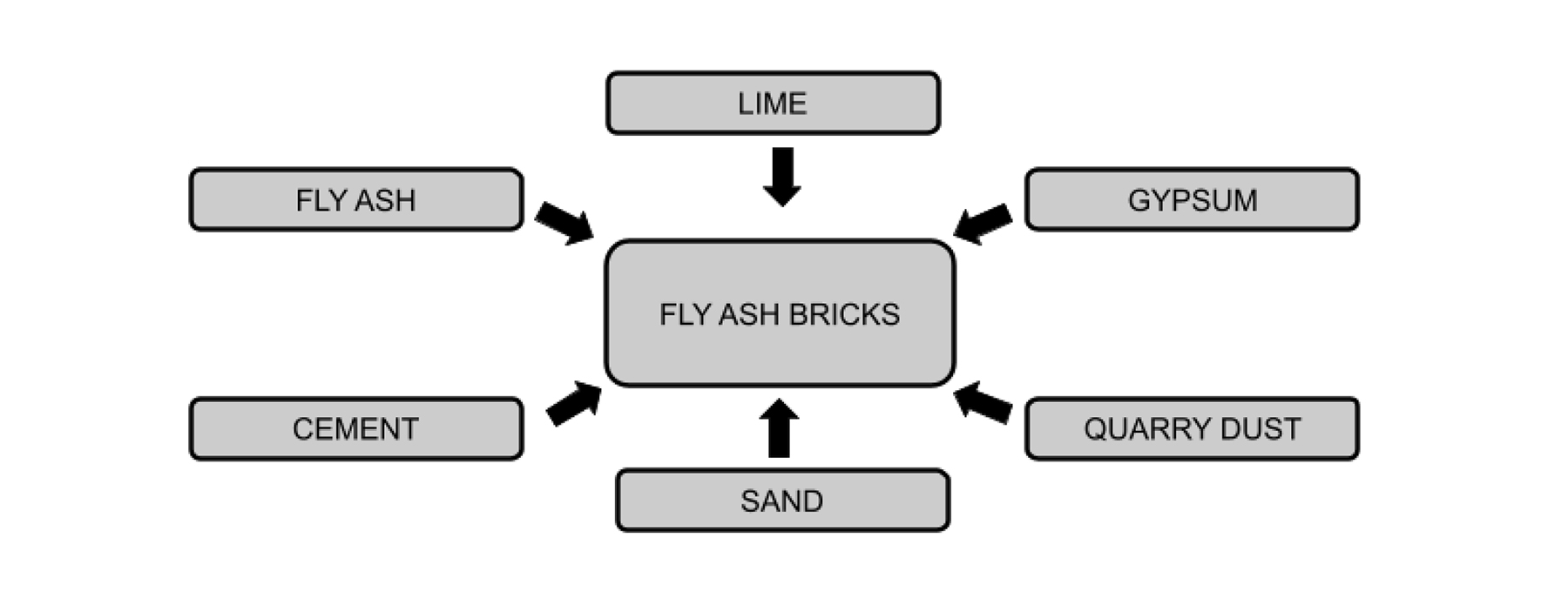

Materials Used to Make Fly Ash Bricks

Fly Ash Brick Manufacturing Process

Fly ash-lime bricks are made by grinding or combining raw ingredients, molding them into bricks, and curing them at varying temperatures and pressures. Crushed bottom ash or sand is occasionally added to the raw material mixture as required.

Mixing the Raw Materials

The raw components, which include fly ash, cement, sand, and water, are mixed in a pan mixer or compounding plant. The mixture of ingredients is then transferred to a brick molding machine.

| Best Builder Floor Apartment in Chennai |

Molding

A machine molding the mixed material into bricks. The machine's hydraulic system compresses the material to the appropriate form and size.

Curing

The bricks are placed on wooden pallets to cure for 7–14 days. The bricks are kept wet during

the curing process to prevent them from shattering and to preserve their durability and longevity.

Drying

Following the process of curing, the bricks are dried in a dryer chamber. The temperature within the drier chamber is kept between 60 and 70 degrees Celsius to eliminate extra moisture from the bricks.

Sorting and Stacking

After the bricks have dried, they are graded according to their quality and strength. Bricks that fulfill the required specifications are stacked and dispatched.

Benefits of Using Fly Ash Bricks:

Appearance

Fly ash bricks have an appealing look due to their cement-like colors, consistent size, and smooth texture. Due to the consistent size, the amount of mortar needed for walls and plastering is reduced by approximately 40-50%.Plaster of Paris (Gypsum plaster), putty can be applied directly without a baking coat of plaster.

Strength

The compressive strength of fly ash bricks is extremely high (9-10 N/mm2). As a result of its superb strength, there are no damages or waste during transportation and handling. The thinner the joints and plaster, the less likely the plaster will crack.

These bricks provide no additional load to the design of structures and provide better earthquake protection. It gains strength with time and provides more strength to the construction.

Thermal Properties

The thermal conductivity of fly ash bricks is 0.90 to 1.05 W/m2. They absorbed less heat. The pozzolanic process of fly ash and lime creates less heat. It keeps your building cool in the summer and is hence best suitable for the Indian climate.

Durability

These bricks are extremely robust and less fluid-filled. The decreased permeability effectively reduces the effect of efflorescence on bricks.

These bricks are less porous, absorbing less water and reducing water on walls. It is also very resistant to mild acids, water, and sulfates.

Soundproofing

Fly ash bricks offer great sound insulation characteristics, absorbing unwanted noise vibrations. This calms the space, insulating you from the chaos of a bustling town or neighborhood.

Also Read: How to Choose Best Cement for Constructions

Fire Resistance

The bricks' high melting point and non-toxic nature ensure that they are not producing dangerous vapors when exposed to fire. Feel confident in your construction knowing that fly ash bricks are extremely fire resistant.

Sustainability

Fly ash bricks are environmentally advantageous since they are formed from waste materials produced after the combustion of coal in thermal power plants. There is no pollution or environmental impact, which makes it a white category product.

Cost

A comparable number of fly ash bricks will cover a larger area than clay bricks. The consumption of mortar is likewise small. Needs less labor. The cost is about 30% less than clay bricks.

— - —